Vacuum

Booster Power Brakes for the FFR Cobra

Forrest B. Allen <forrest1@home.com>

While building, from talking to FFR

owners, and watching the Forum postings, I got the impression that a lot of

people are not really happy with the brake pedal force needed with the manual

brakes, and that this gets worse with rear discs. I have IRS, so I decided to

just use the vacuum booster, since it was *free*.

The booster lines up with the pedal

cage, and they fit together just as they did in the

donor, with the front wall of the

driver footbox sandwiched in between. You will need to enlarge the hole for the

little bellows around the vacuum booster rod to the brake pedal. I just used the pedal box as a template to

mark where to cut this out.

The booster would hit the lower 3/4" frame tube that runs

from the wall of the footbox to the front frame below the upper control arm

mount point, so I cut out a section of the tube and welded back a 3/4"

piece on the lower outside of the original tube, which gives the necessary

clearance.

If you look at photo 2 you can see

both ends of the new frame tube where it's overlapped. If I did it again, I

would run the new frame tube all the way down to the front frame "X",

and lengthen the vertical tube (that holds the front pillow block) a little to

meet it. Then it would be very hard to see the modification, because the upper

overlap is hidden inside the drivers footbox. --I did mine after the

"F" aluminum was already on, so I didn't think of that until too

late. I should have drilled out the rivets and removed the “F” panel

temporarily.

The master cylinder will be very close

to the front wheel gravel guard, and the guard will need a “dimple” or just cut

about a 1” hole, like I did. It might

be possible to avoid this with a different (shorter) master cylinder, but it

any case it is not a big problem.

The master cylinder also winds up sort

of under the fender, and will be a little harder to fill, but works. Be careful where you mount your coil and

wiring, or it may be difficult to reach.

I mounted my coil on the firewall, running the high-voltage lead under

the EFI manifold. I shortened the

primary wires to the coil, which come up that harness anyway (credit for this

idea goes to Roger Stine).

I used an '81 Mustang power brake m/c

(Autozone M1764) instead of the donor, because I am running IRS and wanted to

use a Wilwood proportioning valve instead of the donor prop valve. So I wanted

a m/c with separate fluid reservoirs for safety in case of a leak. The donor

has a common reservoir, the donor prop valve is what cuts off a leak at either

end of the system. The '81 m/c measured out at the same depth for the actuating

rod from the booster, so I just bolted it on.

ADDENDUM 26 Oct 2001: I've had some

trouble with insuffiicient rear braking due to using the ’81 m/c, which is a

disk/drum m/c and does not have enough cylinder stroke capacity for the rear

discs. I plan replace it this

weekend--see discussion on this CobraForum thread:

http://www.cobraforum.com/cgi-bin/ultimatebb.cgi?ubb=get_topic&f=1&t=020247

If you are running disc/drum, the

stock m/c and prop valve (modified per Matt90GT) is a good

choice. If you are running disc/disc,

you'll need either a 94-96 GT V6 MC, which has metric (bubble flare) ports,

just like the stock m/c, that will mate with the original lines to the stock

proportioning valve, which must be modified per Matt90GT if you will be using a

Wilwood or other adjustable proportioning valve. Why modify the stock valve?

Here is Matt’s explanation: “Also if you are using the stock 87-93

Mustang combination valve (the block below the MC in the mustang) it contains 2

parts. A shuttle valve accessed via the rear plug (the small one) which will

move over to close if you lose pressure in one brake circuit. This will give

you the other brake circuit with which to stop with. Basically a safety feature

incase of failure or leak. The front part of the combination valve is the stock

proportioning valve. If you want to use the stock combination valve with an

adjustable unit, you HAVE to defeat the stock PV. You do this buy purchasing

FMS M2450-A plug ($7-10 at any FMS dealer). To finish the modification, you

remove the stock endcap (you cannot leave this in because of the rubber plug in

it. That is usually sealed against the rod. remove the rod and then it is

exposed to up to 1000PSI and rotting from the brake fluid), transfer rubber O

ring to the FMS plug, remove the spring, spring seat and rod. Then ONLY install

the FMS Plug. defeats the stock PV and allows you to run an aftermarket

adjustable one. “

Alternatively, you can do as I am

doing, trash the donor proportioning valve,

and use a Wilwood valve for the rear brakes, in which case you will want

to get a 1986 Mustang SVO Turbo 4cyl mc (NM1897 at Autozone, $52.99), which has

SAE inverted-flare threaded ports which will match the pre-flared tubing that

you will probably be using (actually, one port is larger and WILL need an

adapter). It also has separate

reservoirs in the m/c, so if one end of the system leaks, the other end will

not be affected, so the shuttle valve is unnecessary. I like to think that this makes the system simpler and

neater. The depth for the actuating rod

is the same as the other 1990 (stock) m/c, and the ’81 m/c (and maybe all

Fords??), so it just bolts onto the

booster.

See Matt Bobbitt’s (Matt90GT)

excellent sites for more info on brake components. His site is directed at Mustang upgrades, and covers many options

applicable to FFR Roadsters:

My booster is a 1990, straight out of

the donor. I don't know for sure, but I would assume that all Fox body boosters

are the same size—except maybe the cobra models?

After installing this, the only

problem was that the brake and clutch pedals were too close to the driver seat

for my comfort. The pictures show how I

lowered them both to a comfortable level.

The brake is easy, just take out the

pivot bolt and move the pivot around until it looks right, then redrill. This is easy if you have a foot-long drill

bit, as I did, otherwise you might have to take the pedal box out yet

again. Or the pedal lever itself could

be reshaped. Even with the reposition,

the wheels lock long before the pedal would run out of travel.

The clutch is a little more tricky,

involving spacers under the return stop, a cut-and-try sort of deal. The Forte’s quadrant allows easy adjustment

so that there is slight throwout preload and so that the clutch releases

completely, as well as being stronger than the OEM plastic unit.

About the gap between the rear end of

the pedal box and the 3/4" tubes: They ALL fit that way. I did what most

people do and put a stack of washers in there. It's quick and easy, and nobody

is going to see it.

A more elegant solution would be to

rebuild the 3/4" frame, welding it to the TOP edge of the 2x2 firewall

tube, which is how it should come from

the factory in the first place, IMHO. The way to do it would be to

cut out the old tubes, bolt the pedal

box onto the front wall, and then use the pedalbox as a jig to fit the

3/4" tubes to the firewall 2x2.

You'd want to do it before the aluminum is on the firewall and footboxes.]

***My thanks to Sergio for taking

these pictures with his digital camera.

Sergio has also mounted the vacuum booster on his car, see his photo

page for additional pics:

Sergio's

photo page:

http://members4.clubphoto.com/sergio312874/guest-1.phtml

***Larry Cornish installed the booster

before I even though of it:

posted

05-25-2001 11:14 AM

Marc,

I

installed the donor booster this last winter and have about 2,000 miles on it.

We have the IRS with stock discs, no proportioning valve and an '84 M/C. The

M/C is a little harder to fill, but it's not like you do this often anyway. The

splash shield needed a 1" hole for clearance. Our install is exactly as

Forrest's.

It

stops straight and true and is sooooooo much more comfortable.

Larry

Cornish

Member

# 247

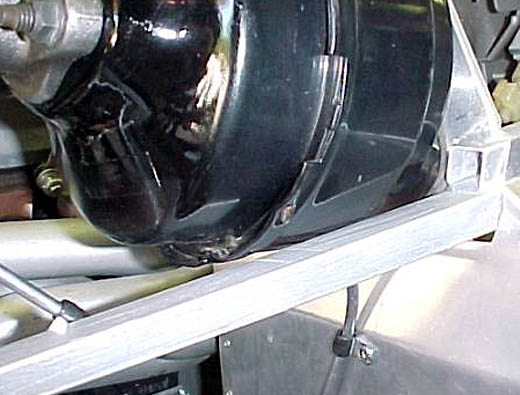

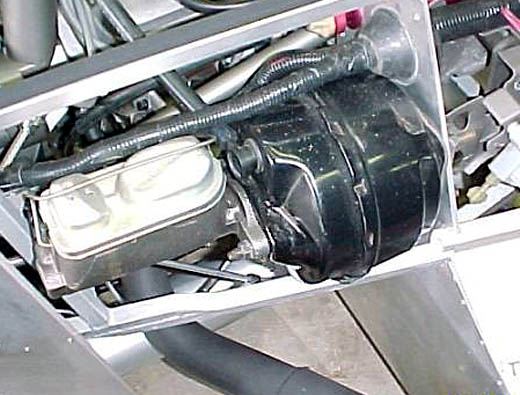

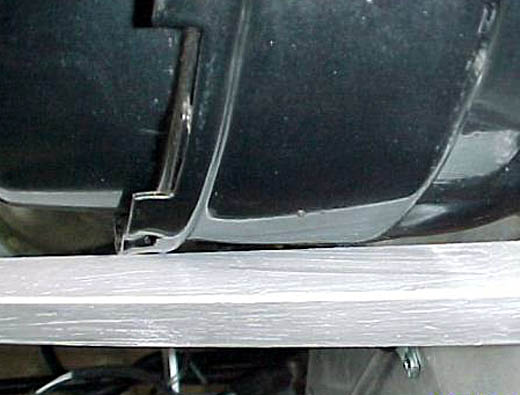

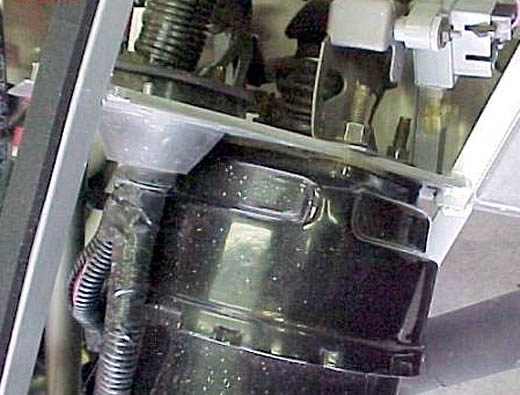

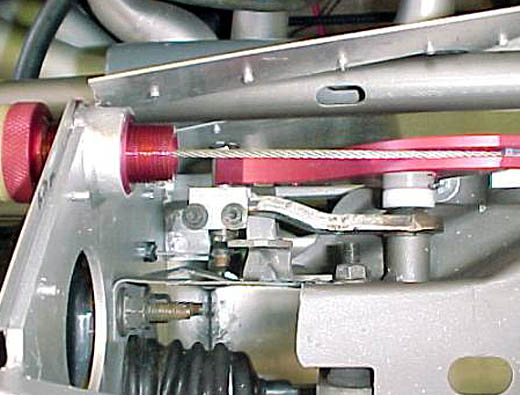

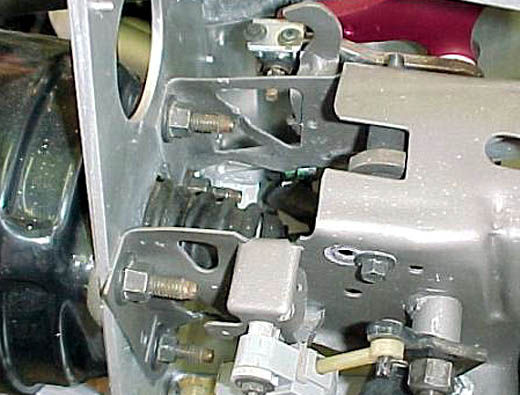

Photographs, with thanks to Sergio:

No, it doesn’t touch the ¾ tube, but close!

Note overlap. Upper

end is totally hidden in footbox, lower end hard to see in finished car, but

could be avoided by extending new ¾ tube all the way to the “X”

Shows how the elephant ear will need a hole or dimple for

the corner of the m/c

Yes, it is close, but no contact. Note that new bar is offset slightly to outside as well as below

old tube.

Ignition coil before moving to firewall (it hit the hood

strut in this position)

top view

Top inside, also shows spacer on clutch arm used to adjust

clutch pedal height lower (a cut and try proposition). Forte’s adjustable clutch quadrant allows

easy adjustment for release with reduced pedal travel.

Shows relocation of brake lever pivot bolt, to lower brake

pedal for comfortable driving position.

Clutch pedal is at same level, using spacers to adjust the return

travel. These mods, along with throttle

pedal “de-tuning” as described in the CobraForum, have made this a very

comfortable car to drive.